Explain the Different Type Welding Defects in Brief

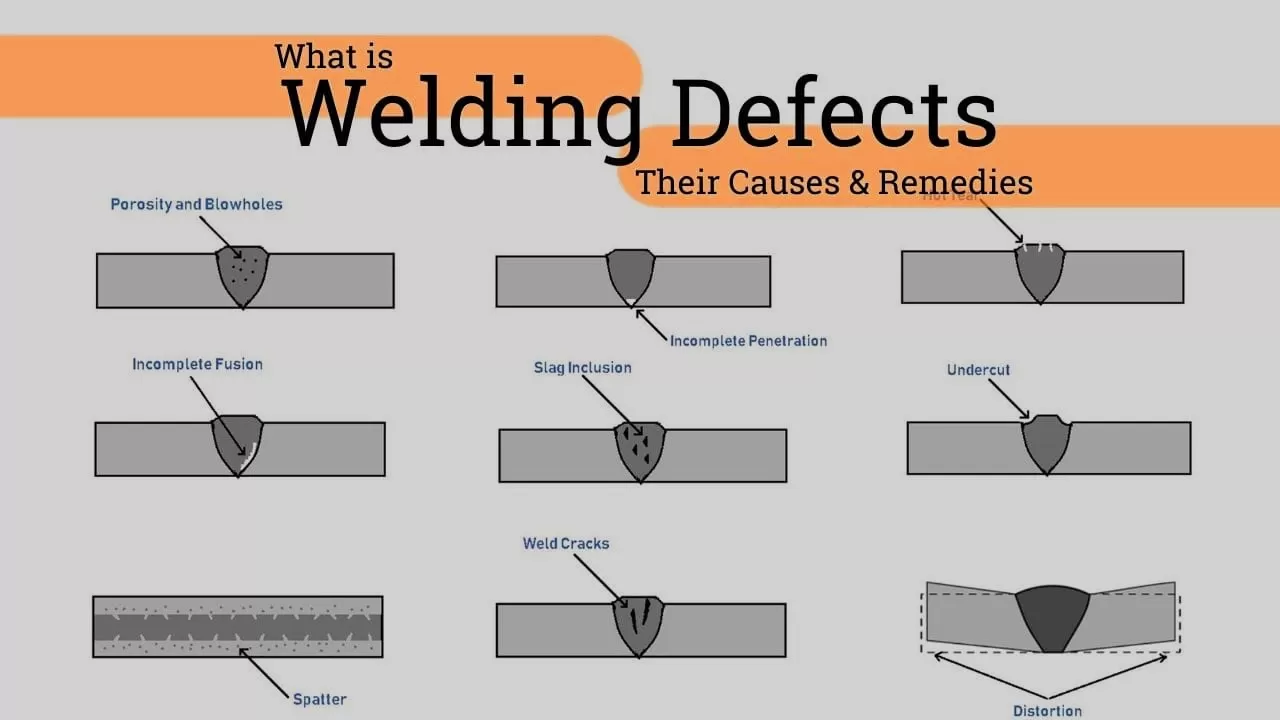

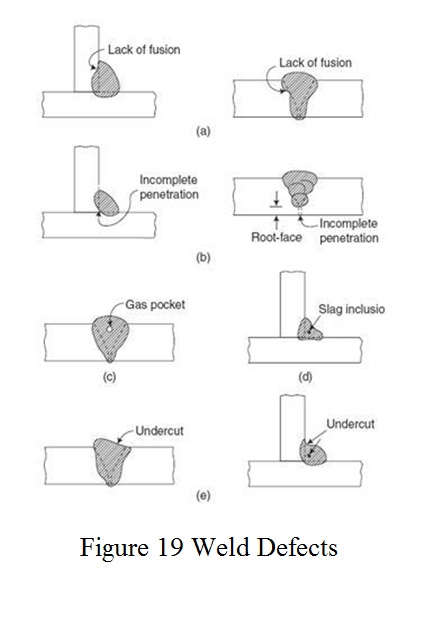

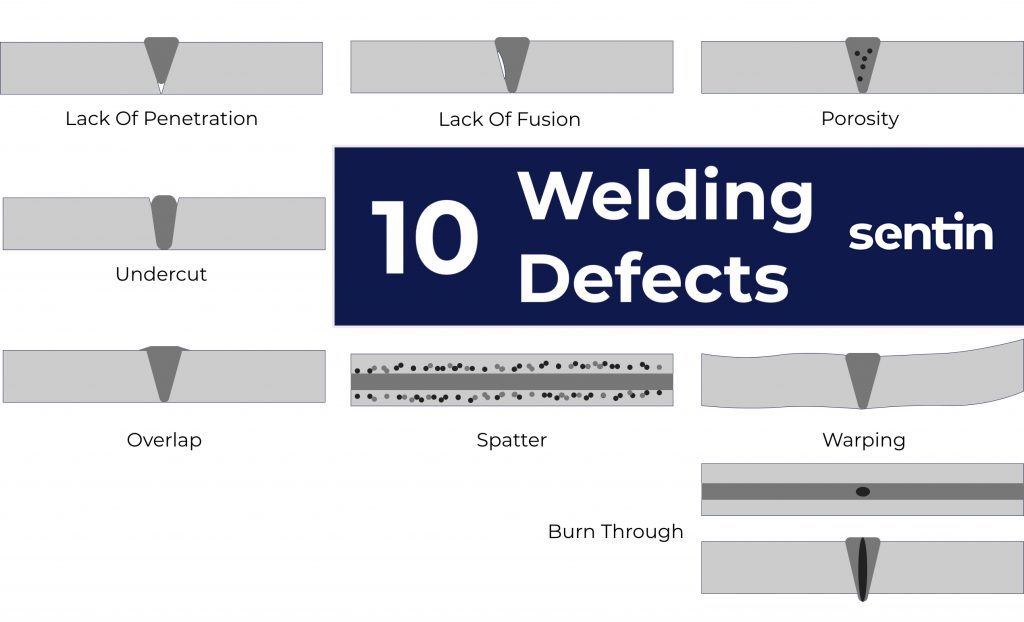

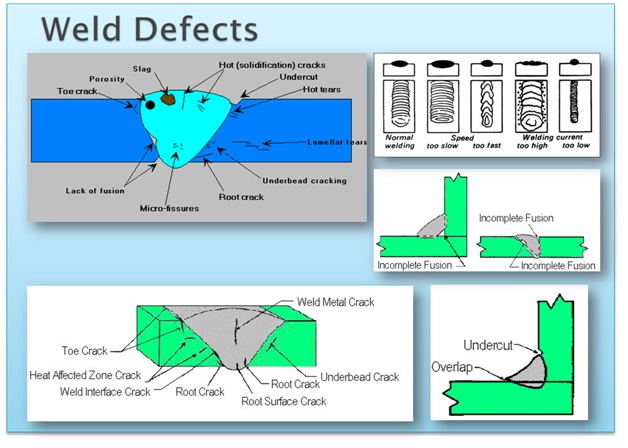

Defects on rolled metals. Porosity slag inclusion and undercut can either called discontinuity or defects.

What Are Types Of Welding Defects Causes And Remedies

Hot tears hot spot.

. Cold shut misrun slag inclusion 5. Any irregularity discontinuity or flaw in the weld metal which exceeds the applicable code limit is termed as a WELD DEFECT. As the name implies in this type of defect some of the forging section remain unfilled.

We can summarize the types of welding defects as follows. Cold shut misrun slag inclusion 5. While welding discontinuities such as.

Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool. Laser Beam Welding LBW Laser Beam Welding LBW is a welding process in which heat is formed by a high energy laser beam targeted on the workpiece. Earn your degree in Welding Engineering Technology from NEIT and begin your new career path today.

The following stated below represent the common types of defects of rolling. Submerged arc welding is a type of arc welding process which involves the formation of an arc between the electrode and the workpiece. This is due to poor design of die or poor forging technic.

Square of angular breaks 5. In this defect air bubbles or gases are present in the weld zone. The flakes defects can cause because of the fast cooled of the upper die which is unable to makes proper forged operation.

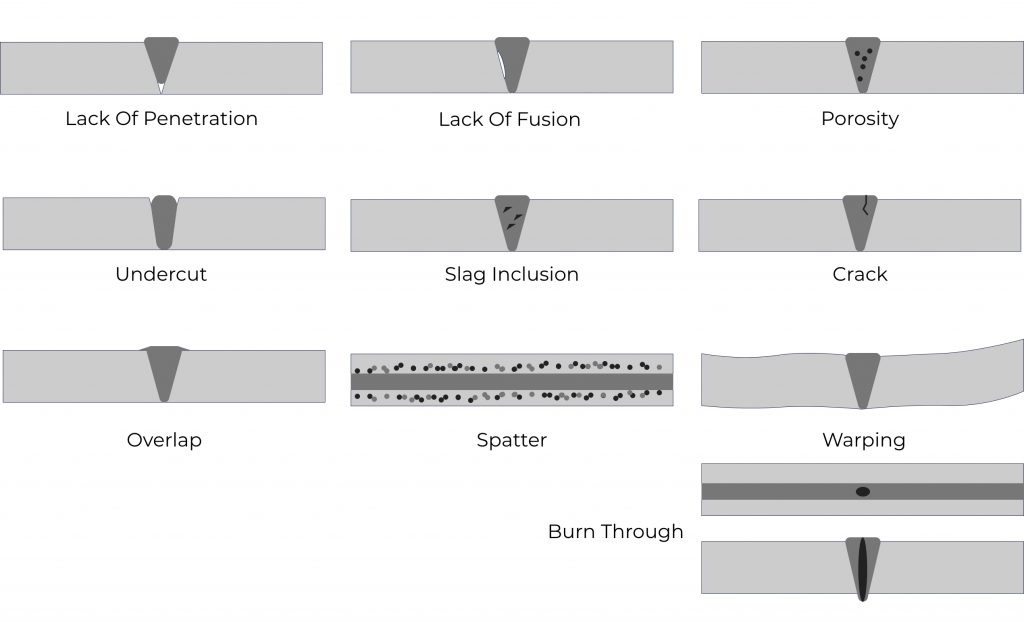

Types of welding defects. Flux-cored arc welding is similar to the metal active gas welding process. Cut and washes swell drops metal penetration rat tail 4.

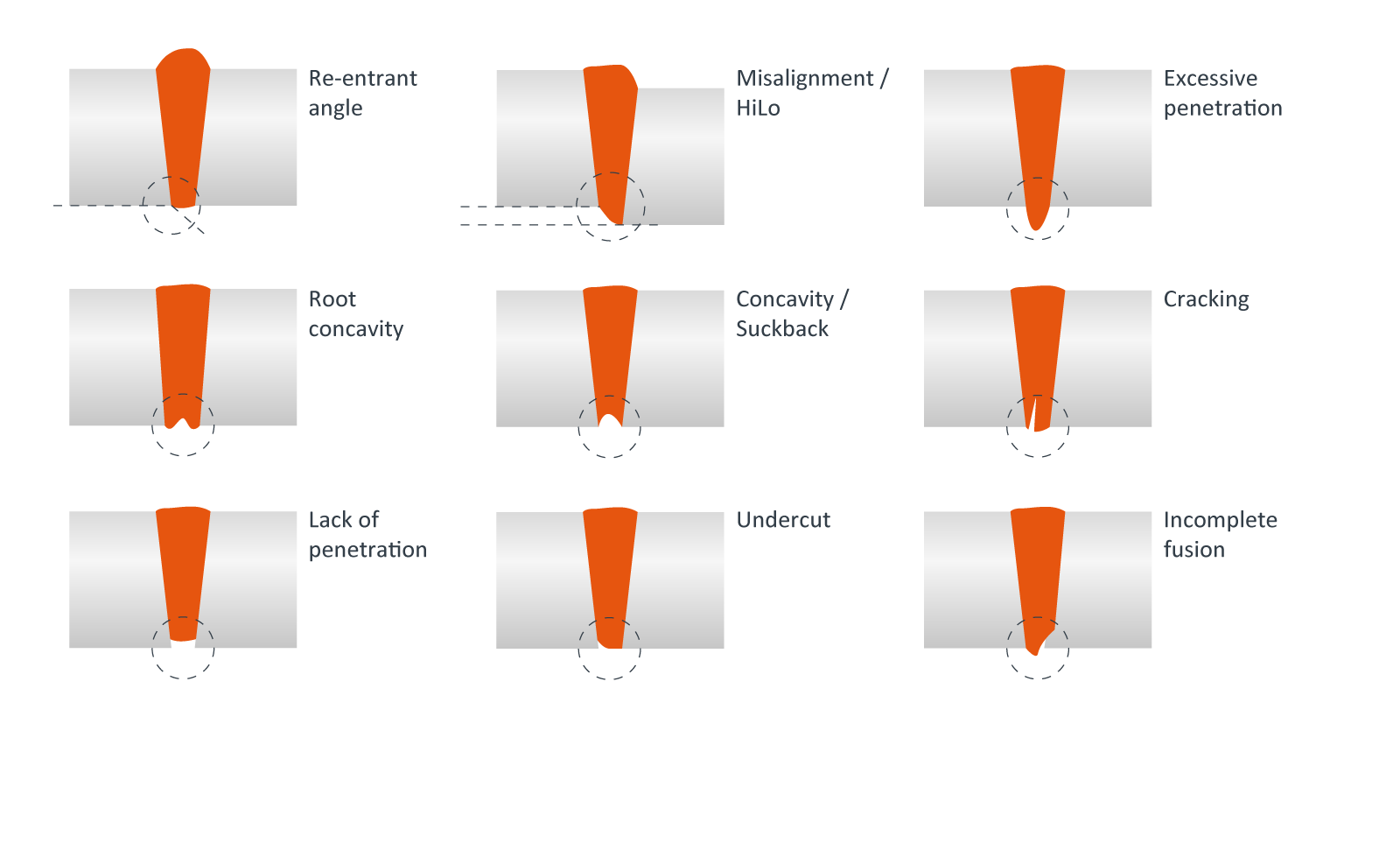

This defect can be removed by proper die design proper availability of raw material and proper. Types Causes and Remedies. Please note that a discontinuity can be termed as a defect only when if it exceeds the specified code limit hence we can say that every defect present in a weld metal is a discontinuity but every discontinuity present in the weld.

Gas Porosity Pinholes Blowholes Open Holes Shrinkage Defects Open Closed Warping Mold Material Defects Cuts and Washes Swells Drops Metal Penetration Rat Tails Fusion Run Out. This is also due to less raw material or poor heating. Heres what this guide will cover.

Groove welds butt welds Groove welds butt welds and fillet welds are provided when the members to be joined are lined up. The completed welded joint may be referred to as a weldment. Welding is usually used on metals and thermoplastics but can also be used on wood.

Groove welds are costlier since it requires edge preparation. Gas Metal Arc Welding GMAWMIG Gas Tungsten Arc Welding GTAWTIG Shielded Metal Arc Welding SMAW and Flux Cored Arc Welding FCAW. The laser beam heats and melts the ends of the workpiece making a joint.

Metal drop expelled from the weld that stick to surrounding surface is known as spatter. General welding defects are Internal porosity. Welding processes are broadly divided into two types.

It is wise for you to always avoid it to train your mind to give your best when doing something. The four main types of welding are. In laser welding LBM the joint is formed as a sequence of overlapped spot welds or as a continuous weld.

These types of rolling defects can occur in different cases which may be caused by the deflection of the compressive load or obtaining thicker result when the middle portion of the rolling part is bent. The distribution of air. Types of forging defects include unfilled section cold shut scale pits die shaft flakes improper grain growth incomplete forging penetration surface cleaning and residual stresses in forging.

START YOUR WELDING CAREER. To avoid this forging defect care should be taken during the operation and the smith must have experience in forging. Types of Welding Defects.

Arc welding is also called as Shielded Metal Arc welding or simply referred to as Stick. Rail length Rail quality Rail section Rail welding Speed of trains etc The above are some of the main reasons of the rail failure 4. This is the most basic of all welding types.

Cut and washes swell drops metal penetration rat tail 4. Casting defects can be categorized into 5 types. Groove welds can be employed safely in heavily stressed members.

Some materials require the use of specific processes. Blowholes open holes pinholes 2. Arc Welding or SMAW Shielded Metal Arc Welding.

Internal welding defects exist in the material at some depth and are hidden from naked eyes. The welding stick uses electric current to form an electric arc between the stick and the metals to be joined. Square butt welds are provided up to a plate thickness of 8mm only.

It is common type. In the pressure welding process joining is done by the application of external pressure or force at the area of contact which causes more or less plastic deformation of both the contact surfaces. In this guide were breaking down six different areas of casting defects to help you pinpoint fix and avoid issues with your castings.

The arc is shielded by a blanket of granular fusible material on the work. Rail failures - Types 1. Even when this type of discontinuity is highly tolerated.

The facing surfaces are heated to some extent in order to permit. Blowholes open holes pinholes 2. To weld iron and steel this type of welding.

You must have to design a proper die to not to perform such defects.

Different Types Of Welding Defects What Is Welding Welding Types Of Welding

7 Most Common Defects In Welding And Its Causes

Different Types Of Welding Defects And Remedies Student Lesson

Illustration Engineering Welding Defects Can Be Stock Vector Royalty Free 1878650152

9 Different Types Of Welding Defects Causes Remedies Pdf

Welding Defects Classification Causes And Remedies Welding Ndt

Different Types Of Welding Defects 14 Download Scientific Diagram

19 Common Types Of Welding Defects Causes Remedies

11 Common Welding Defects And How To Prevent Them Welding Troop

Different Types Of Weld Defects Download Table

Welding Defects Cause And Remedies Youtube

Welding Defects Types Causes And Remedies With Pdf Quiz

Welding Defects Weld Defects Causes Remedies Porosity Arc Strikes Undercut Welding Process Youtube

The 10 Common Weld Defects You Should Know Sentin

What Are Defects Or Faults Of Welding Marinegyaan

The 10 Common Weld Defects You Should Know Sentin

Most Common Welding Defects Oms Optical Metrology Services Ltd

What Is Welding Defects Types Causes And Remedies The Welding Master

Comments

Post a Comment